Pruftechnik's Rotalign Touch is a powerful instrument designed to enhance the reliability of your rotating equipment. This cutting-edge technology utilizes innovative laser alignment methods to ensure precise adjustment of shafts and bearings, minimizing vibration, wear and tear, and ultimately extending the lifespan of your assets. By proactively identifying potential concerns before they escalate into costly downtime, Rotalign Touch empowers you to achieve optimal equipment performance and maximize overall productivity.

Using its intuitive touch screen interface and comprehensive data analysis capabilities, Rotalign Touch provides real-time insights into the condition of your machinery. Operators can efficiently perform alignments, generate detailed reports, and track historical data to enhance maintenance schedules and reduce unplanned outages.

Achieve Precision Alignment with IRISS Flex-IR

Gain unrivaled accuracy and performance when aligning your essential equipment with the IRISS Flex-IR. This innovative system boasts a high-performance optical alignment read more system that ensures precise alignment. The Flex-IR's intuitive interface and adaptable design allow for seamless integration across a wide range of applications.

Maximize Lubrication Management with SDT Lubexpert

Effectively managing lubrication systems is paramount for equipment lifespan and overall efficiency. SDT Lubexpert delivers a comprehensive platform to streamline your lubrication management, reducing downtime and enhancing operational outcomes.

This innovative system leverages cutting-edge capabilities to track your lubrication program, providing valuable insights for informed decision-making.

- Primary features of SDT Lubexpert include:

- Automated lubrication tracking

- Early alerts to prevent costly breakdowns

- Reduced downtime and maintenance costs

- Optimized equipment lifespan and results

Smart Solutions for Predictive Maintenance: A Comparison

Predictive maintenance is disrupting the industrial landscape by enabling proactive intervention to potential equipment failures. Employing cutting-edge technologies like machine learning and sensor networks, smart solutions can accurately predict maintenance needs, minimizing downtime and enhancing operational efficiency. This article will delve into a analysis of various smart solutions for predictive maintenance, highlighting their strengths and limitations to help organizations make informed decisions.

- Numerous key factors will be analyzed, including data acquisition methods, processing techniques, and the ability to integrate with existing systems.

- Furthermore, real-world case studies will demonstrate the practical applications and outcomes of different predictive maintenance approaches.

By illuminating the diverse landscape of smart solutions, this article aims to equip decision-makers with the knowledge needed to implement effective predictive maintenance strategies for their specific circumstances.

Streamlining Industrial Asset Management: Pruftechnik

In today's dynamic industrial landscape, maximizing operational efficiency and minimizing downtime is paramount. To achieve this, robust asset management strategies are crucial. Renowned players in the field, such as Pruftechnik, provide comprehensive solutions to streamline industrial asset management processes. These companies offer a wide range of tools and technologies designed to optimize asset performance, provide reliability, and reduce maintenance costs. Through their innovative solutions, Pruftechnik empower industrial organizations to make data-driven decisions, proactively manage assets, and ultimately boost overall operational excellence.

- Utilizing advanced sensors and analytics, these companies enable real-time observation of asset health, enabling early detection of potential issues.

- In-depth maintenance plans can be developed and applied, minimizing unplanned downtime and extending asset lifespan.

- Streamlined data management systems provide valuable insights into asset performance trends, allowing for forward-thinking maintenance scheduling and resource allocation.

Cutting Edge Technologies for Maximized Operational Efficiency.

In today's rapidly evolving business landscape, organizations are continuously to optimize their operations and achieve sustainable growth. Cutting-edge technologies have emerged as powerful tools for enhancing operational efficiency, empowering businesses to optimize processes, maximize productivity, and gain a competitive edge. From artificial intelligence (AI) and machine learning (ML) to cloud computing and the Internet of Things (IoT), these transformative technologies are disrupting industries across the globe.

Applications of these cutting-edge solutions allow businesses to process vast amounts of data, identify actionable insights, and make informed decisions. By leveraging AI-powered automation, organizations can reduce manual tasks, improve accuracy, and redirect human resources to more complex activities.

- Furthermore, cloud computing provides flexible IT infrastructure, enabling businesses to adapt quickly to changing demands. The IoT connects devices and generates real-time data, providing valuable insights into operational processes and enabling predictive maintenance.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Pauley Perrette Then & Now!

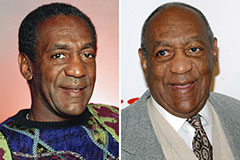

Pauley Perrette Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!